Quick reference table with forms, materials, sizes, classes, and end connections.

| Strainer Form | • Casted • Forged up to 2’’ • Fabricated |

|---|---|

| Material Grade | • Cast Iron • Ductile Iron • Carbon Steel • Stainless Steel • Duplex Stainless Steel • Super Duplex Stainless Steel • Monel • Inconel • Titanium • Internal Weld Overlay (Inconel) • FRP/GRP |

| Size | 1/2’’ to 60’’ (15 MM to 1500 MM) |

| Rating / Class | • ASME #150 / #300 / #600 / #1500 • ASME #2500 • API #3000 PSI / 5000 PSI / 10000 PSI • EN PN 10 /16/30 • AWWA |

| End Connection | • Flanged End • Screwed End • Socket Weld End • Butt Weld End • Graylock / Banlock • Victaulic End |

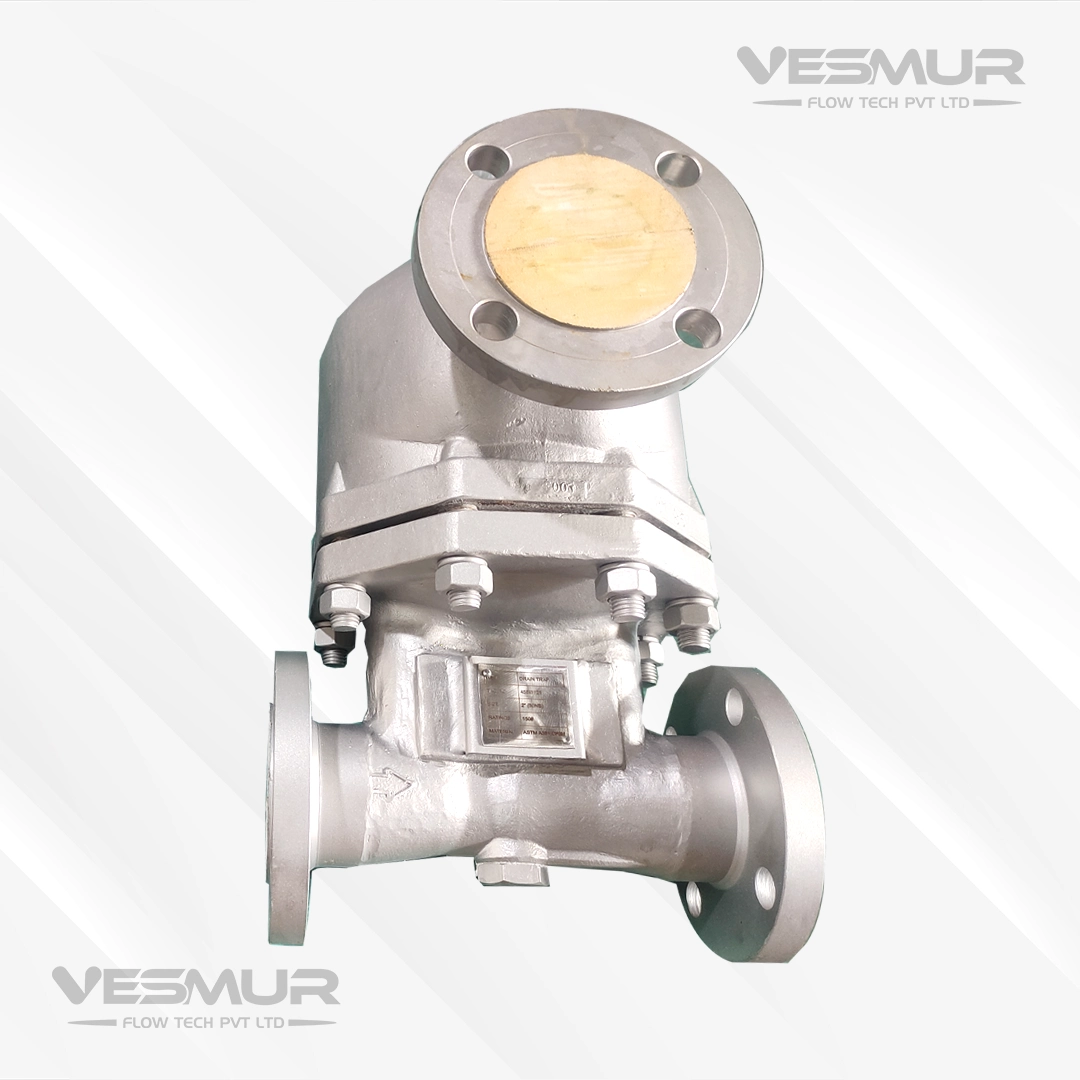

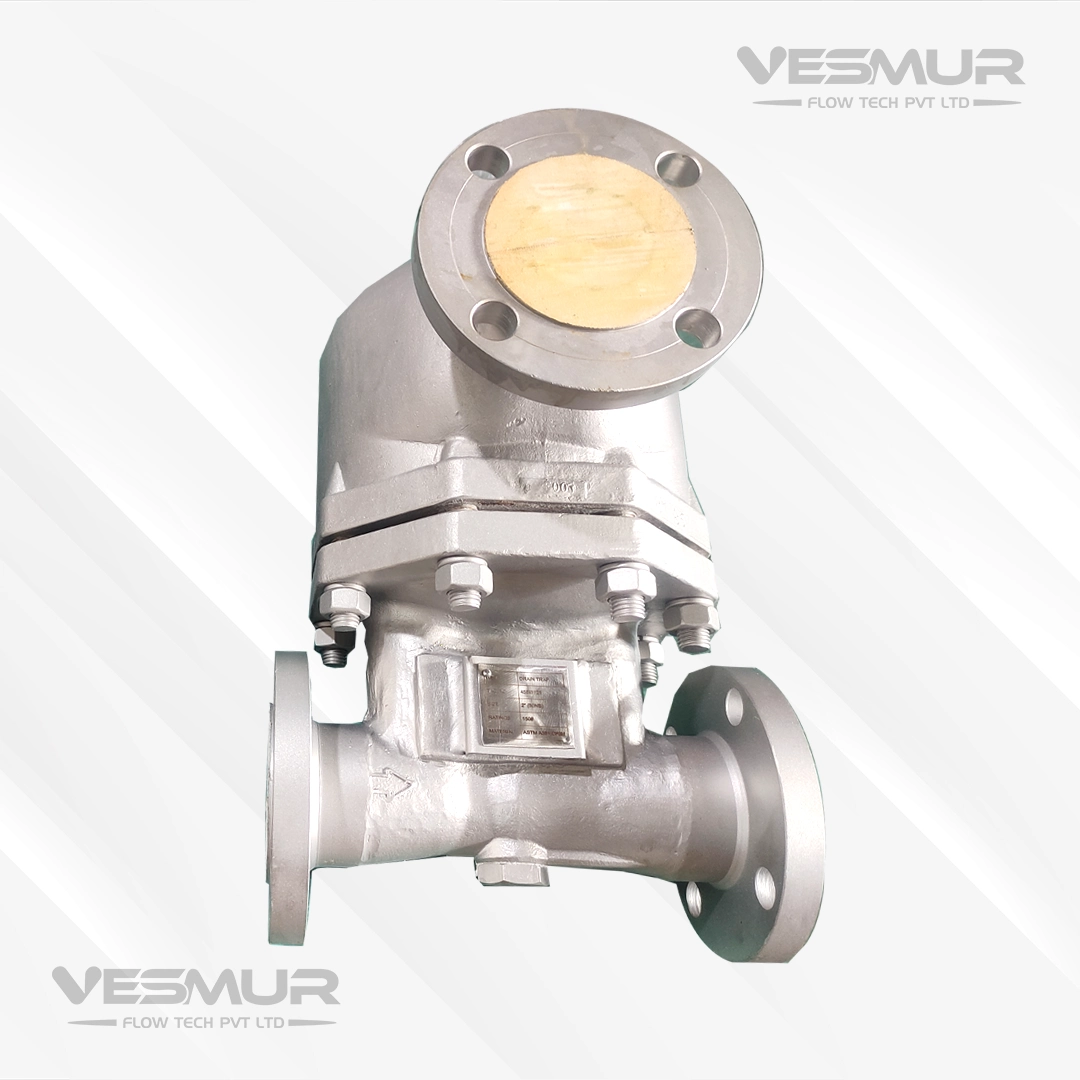

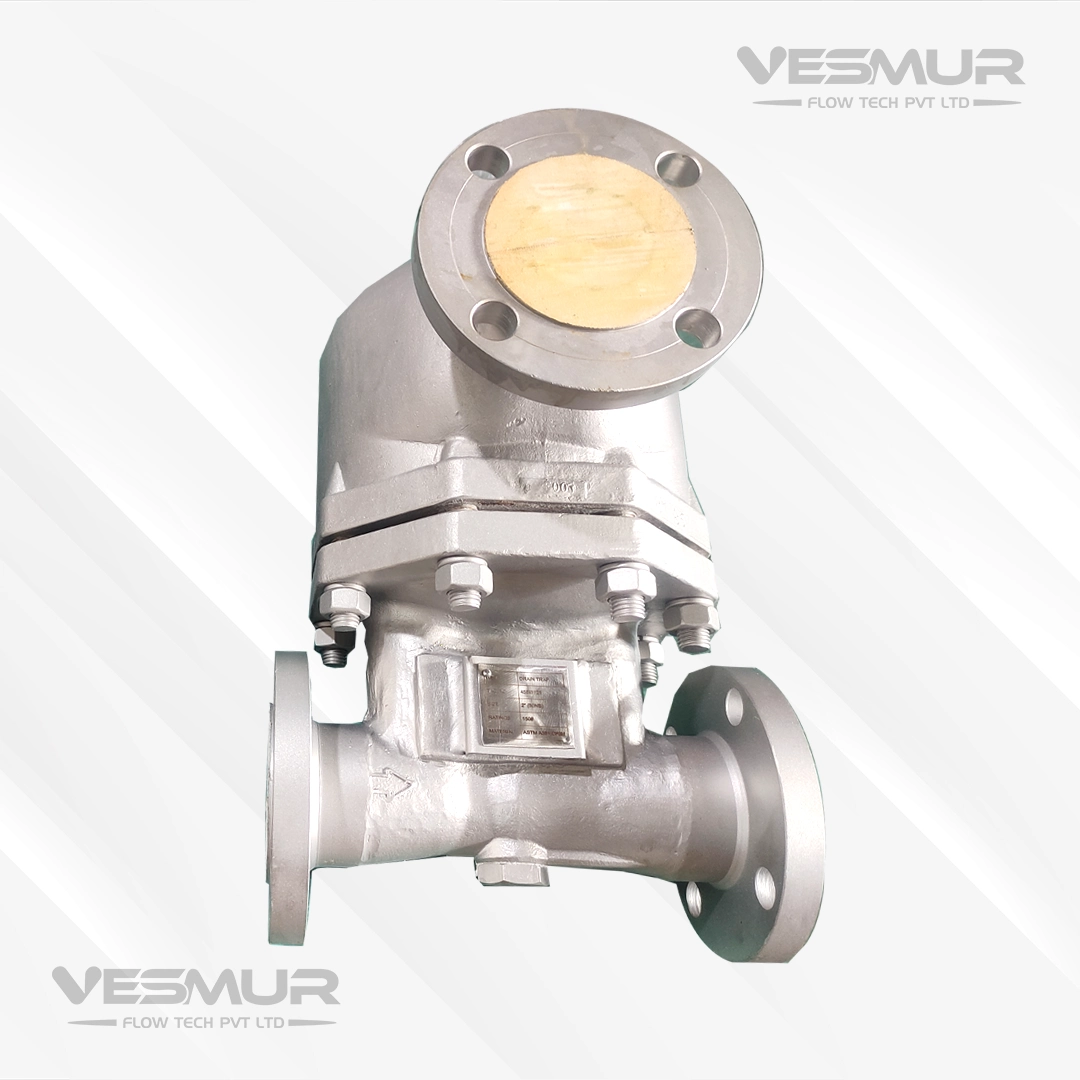

Vesmur Flowtech, based in India, is a leading manufacturer and supplier of high-quality Tee Strainers for various industrial applications. With a strong focus on engineering excellence and customer satisfaction, Vesmur Flowtech delivers durable and efficient straining solutions that ensure fluid systems remain free from debris and contaminants. Our expertise in filtration technology and advanced manufacturing processes allows us to provide top-tier products that meet the stringent demands of various industries.

A Tee Strainer is a mechanical filter designed to remove debris such as dirt, rust, and other solid particles from liquid and gas systems. It features a compact T-shaped design with a perforated or mesh-lined straining element to capture contaminants effectively. Tee Strainers are commonly used in pipelines where space constraints require a streamlined and efficient filtration solution.

At Vesmur Flowtech, we manufacture Duplex Strainers in a wide range of sizes, materials, and configurations to suit various industrial needs. Our product range includes:

Precision Tee Strainers for Efficient Fluid Control

Regions we serve